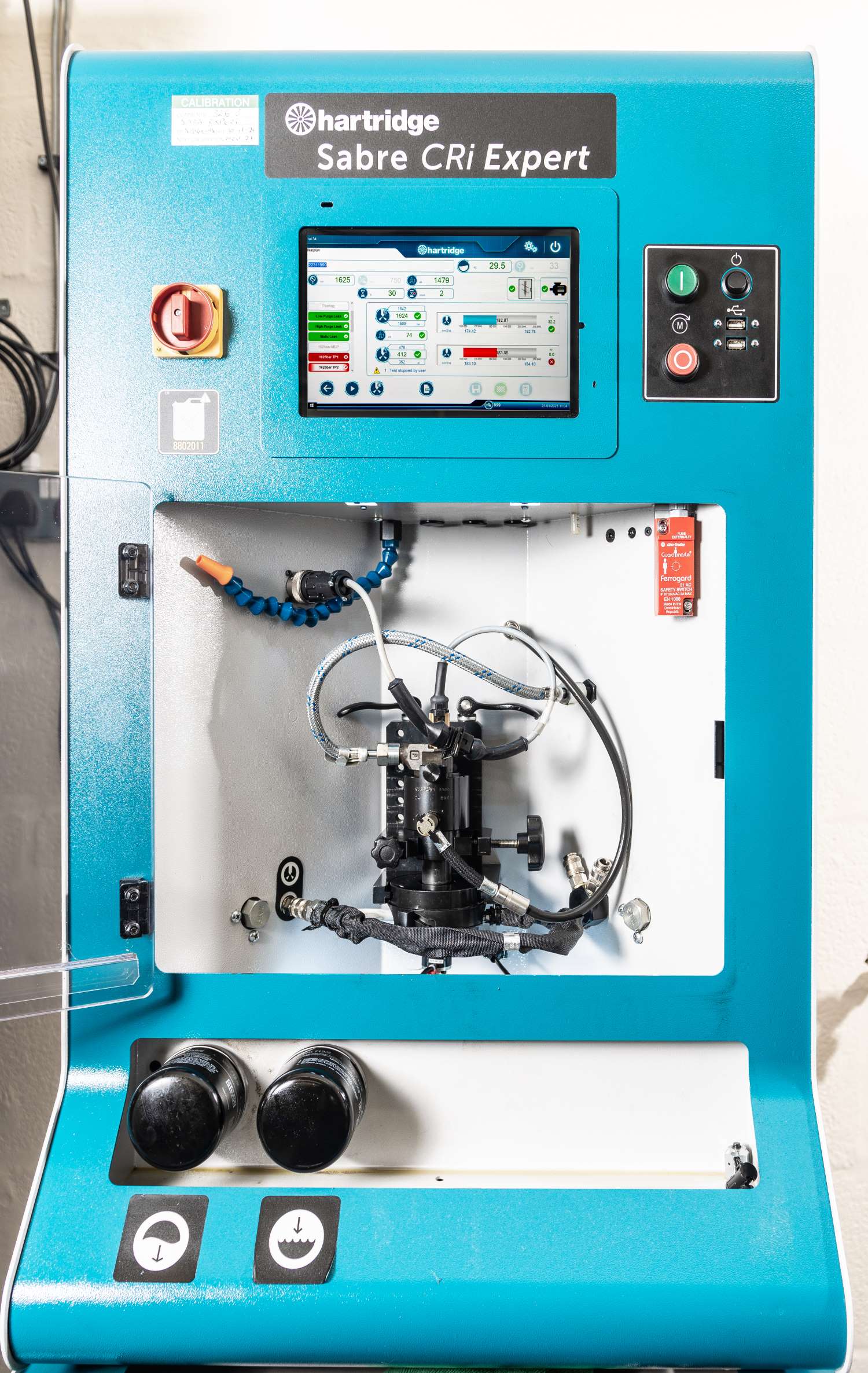

Extract Engineering have the most advanced, up to date and comprehensive Common Rail Diesel Fuel Injector test equipment in Cumbria. We can test all common rail diesel injectors manufactured by VDO, Denso, Delphi and Bosch - including the Smart Piezo designs. We use the Hartridge Sabre CRI Expert which is the most advanced multi-brand common rail injector test bench available on the market.

The Sabre CRi Expert is capable of testing upcoming high pressure common-rail diesel injectors including:

Euro 6 heavy duty Delphi F2X injectors, Euro 4 Delphi Smart, Bosch 117 family, Bosch CRIN twin coil injectors, and Denso i-ART

Pressure testing up to 2700 bar.

Unlike other methods of measuring injector response time which only monitor electrical signals to determine solenoid actuation, Hartridge measures the full event. FERT includes all internal elements of the injector to give you a complete view of the response time of the injector from electrical activation to the injection event.

Built into the software are a number of additional test steps to offer further levels of expert diagnostics for the latest high-pressure applications. Nozzle Opening Pressure (NOP) checks for correct mechanical function of the nozzle to open at the required pressure to achieve the intended atomisation.

Minimum Drive Pulse (MDP) is a dynamic delivery sweep test that provides the MDP measurement & also the ability to determine the profile of the delivery curve thanks to the new graph functions implemented into the magmahTouch software. These are additional tests, but we run them as standard.

Specific testing has also been developed for the new internal pressure sensor in Denso’s latest injector technology, i-ART, measuring the fluctuations of pressure to ensure accurate testing. Thanks to these enhanced features we can offer a wider range of services.

How We Test Common Rail Systems

Extract Engineering's fuel injector flow testing process is very comprehensive. Prior to a full injector test on one of our test benches, we initially test solenoid injectors with the Delphi YDT720 and piezo injectors with the Bosch FSA 050 electrical test machines. These tests ensure that the injectors insulation, inductance and resistance are within specified limits.

Hartridge Sabre CRI Expert

The Hartridge Sabre CRI Expert test machine incorporates features which have been designed to future proof testing in an ever changing market. It allows us to test existing and emerging common rail technologies at very high pressure, up to 2700 bar (39000 psi).

We can now test the following types of injectors -

- Euro 6 & Bosch CRIN 4.2 twin coil injectors, which are increasingly being used in all types of commercial vehicles

- Delphi Euro 6 commercial injectors

- The latest Bosch 117 family injectors

- Denso I ART injectors

How it works

Upon completion of the injector test, we provide a very comprehensive test report. This includes results from multiple injection events including fuel delivery, back leak, response time, nozzle opening pressure, minimum drive pulse new coding if required.

We are more than happy to discuss these results with you in detail and offer you the most cost-effective solution to your issues, whether that is reconditioning your existing injectors or supplying new injectors.

By testing your injectors and ensuring they are within specification your fuel efficiency and therefore emissions will be improved on your diesel vehicle.

DIESEL INJECTOR RECONDITIONING SERVICE

We also offer an in-house injector reconditioning service. Faulty injectors are stripped, undergo an intense ultrasonic cleaning process and are reset using genuine parts where available.

This service comes with a one-year guarantee as standard, subject to terms and conditions, with the exception of reconditioded VDO injectors, which come with a 6 month warranty, subject to terms & conditions.